OUR BUSINESS

By making use of infinite possibilities of synthetic resins as main raw materials, we have been providing numerous kinds of high-quality and high value-added products under our integrated production lines with our original product development expertise, to meet all kinds of customers’ needs.

Our brand “Tarpee” for laminated woven products made from PE(Polyethylene) or PP(Polypropylene), has been highly evaluated in Japan and overseas for a long time, widely used in many fields ranging from Industry, Construction, Civil engineering, Agriculture, Stockbreeding, Packaging, Logistics etc. We provide products with the basic function Waterproof, with the marketing changing trends, Anti-ultraviolet, Flame Retardancy, Reflection, Heating Suppression, Black-out performance are developed to meet various requests. Furthermore, we produce special products for professional applications including gas, oil protective material.

We have the factories of yarn manufacturing, weaving, laminating and fabricating process, could provide you woven fabric, laminated cloth, laminated sheeting, finished products such as ready made tarpurlins, covers, bags as well.

We have a wide range of products and solutions available, and we are always thinking about the next improved product. We would like to produce best performance product for each of you.

How to produce tarpaulin

-

Resin

Using virgin polyethylene resin

Using virgin polyethylene resin -

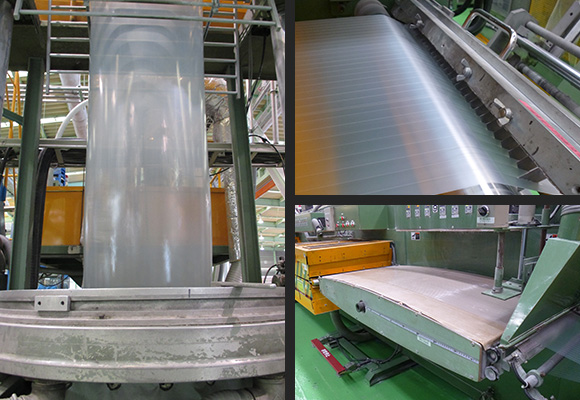

Yarn Manufacturing Process

Melted resin formed to round film by extruder. Cut the film to tapes and stretch to make them thin but strong.

Melted resin formed to round film by extruder. Cut the film to tapes and stretch to make them thin but strong. -

Weaving Process

Weave yarns to fabric by several types of weaving machines.

Weave yarns to fabric by several types of weaving machines. -

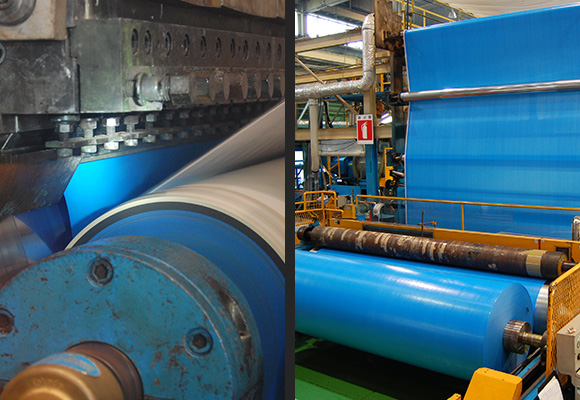

Coating Process

Coating by resin film to produce laminated fabric up to approx. 3.6m(144inch). Roll products are also available for international shipping.

Coating by resin film to produce laminated fabric up to approx. 3.6m(144inch). Roll products are also available for international shipping. -

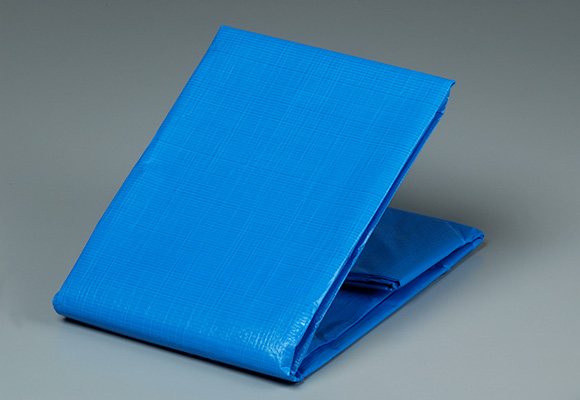

Fabricating

Arrange pe sheeting to required size, produce ready made tarpaulin with reinforcement.

Arrange pe sheeting to required size, produce ready made tarpaulin with reinforcement.