Rewinding and Covering

Today, we would like to explain about the process we have after finish making our products.

Our products are usually 3.6m wide and they are more than few thousands meter long in the first place.

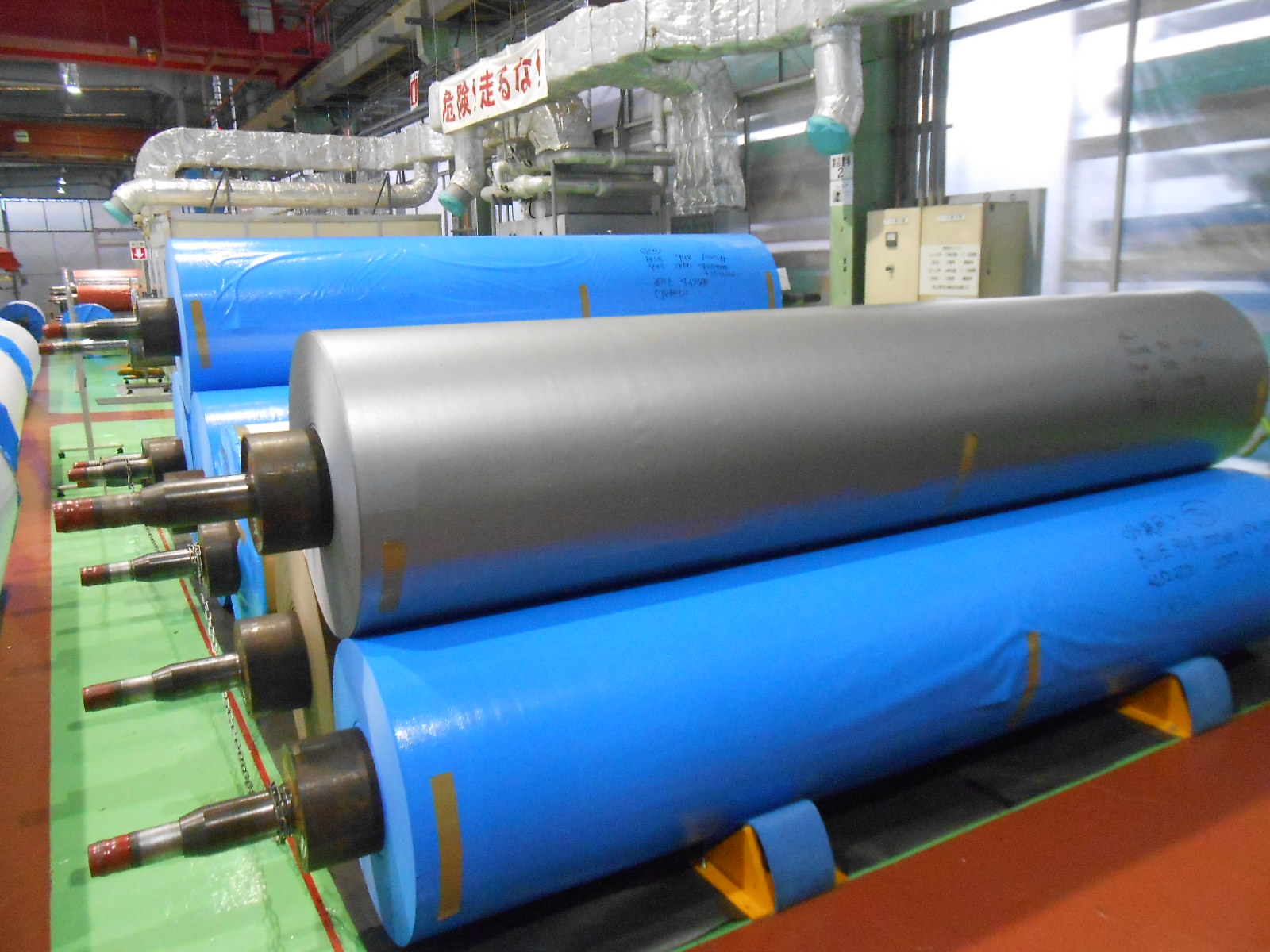

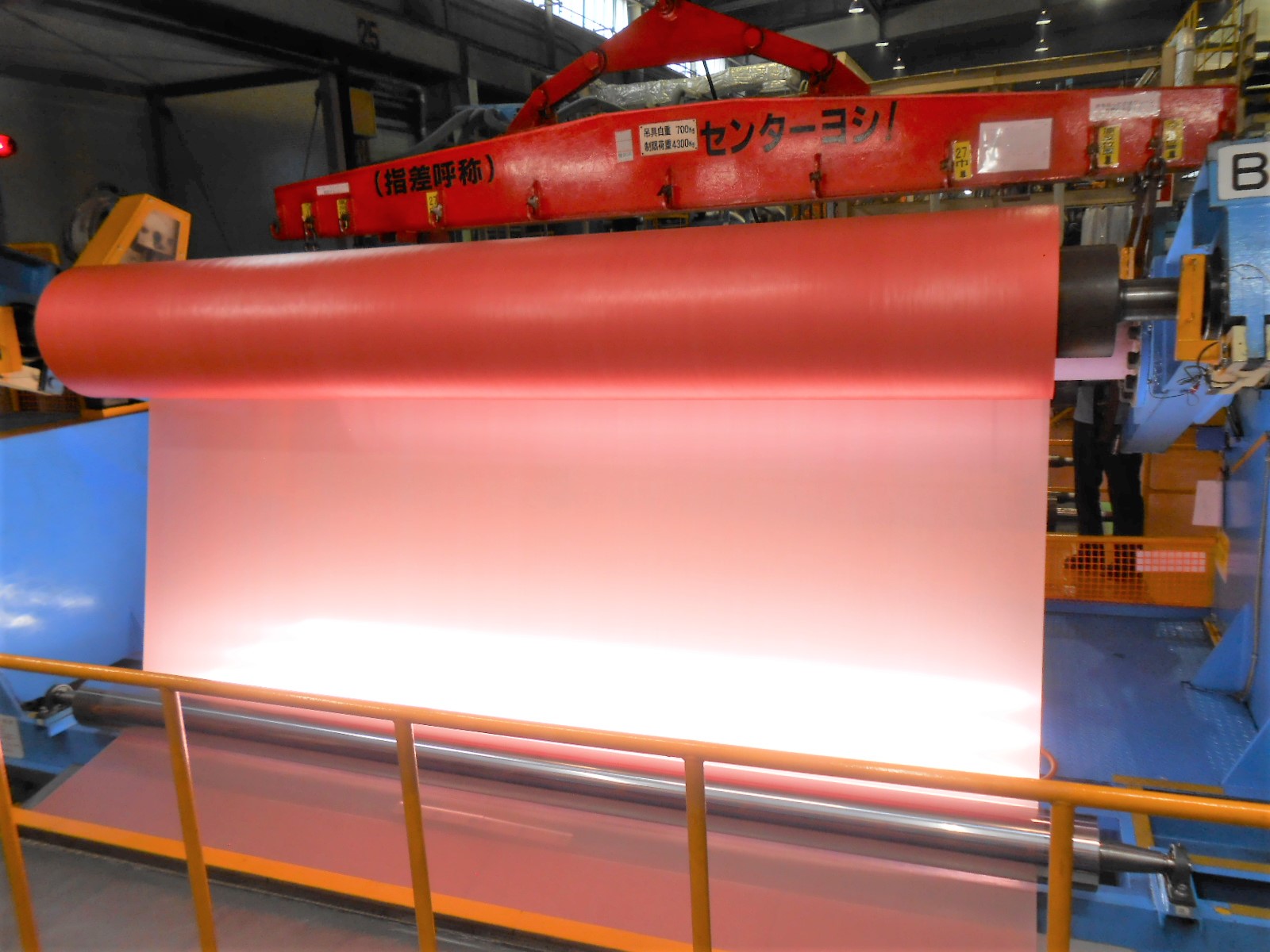

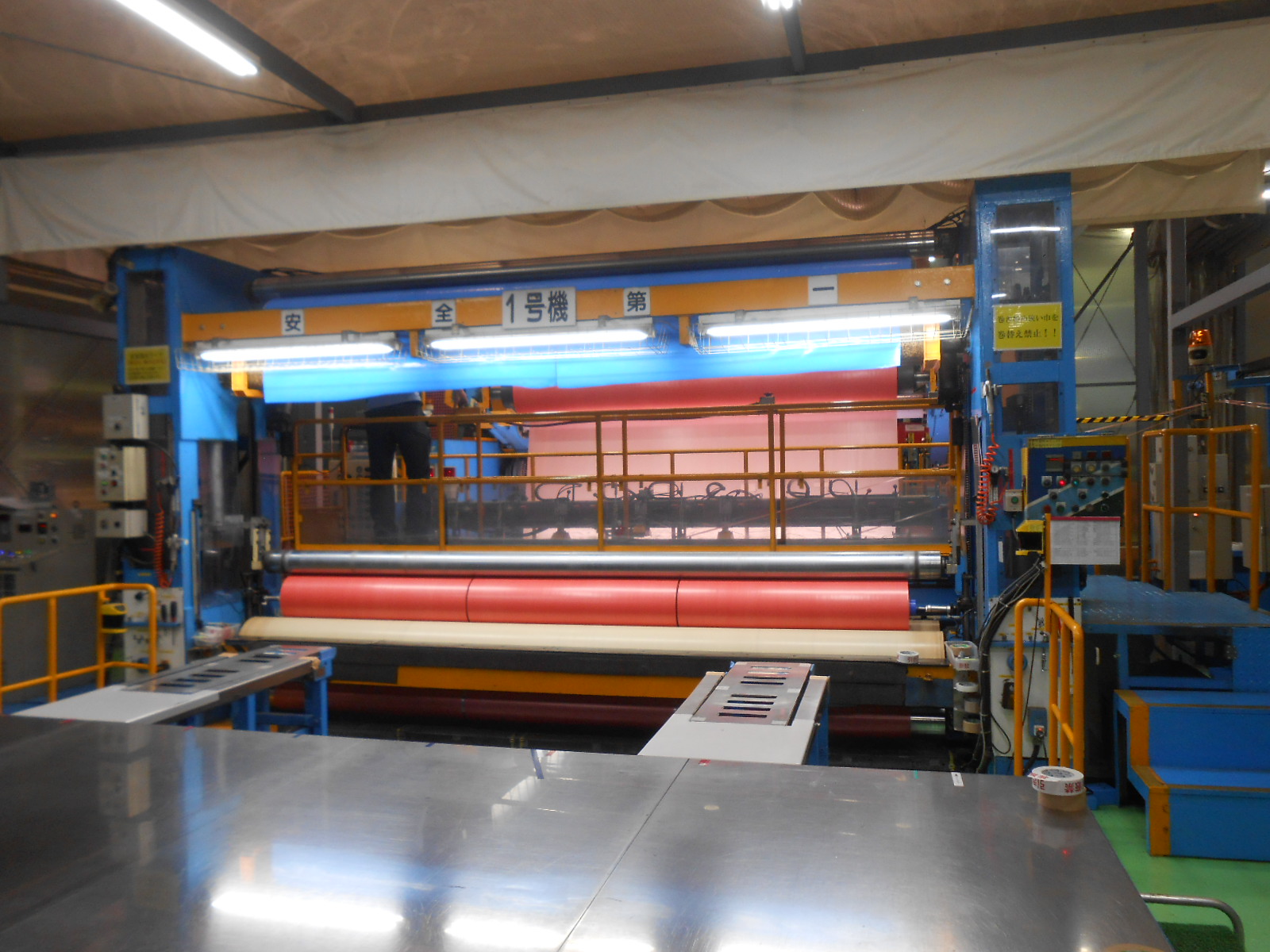

So we have a “Rewinding process” where we rewind and make it into specified length.

Not only rewinding the roll, we also inspect the product for the last time and we split into specified width.

After we made the products into specified width and length, we have a process where we get ready for shipment.

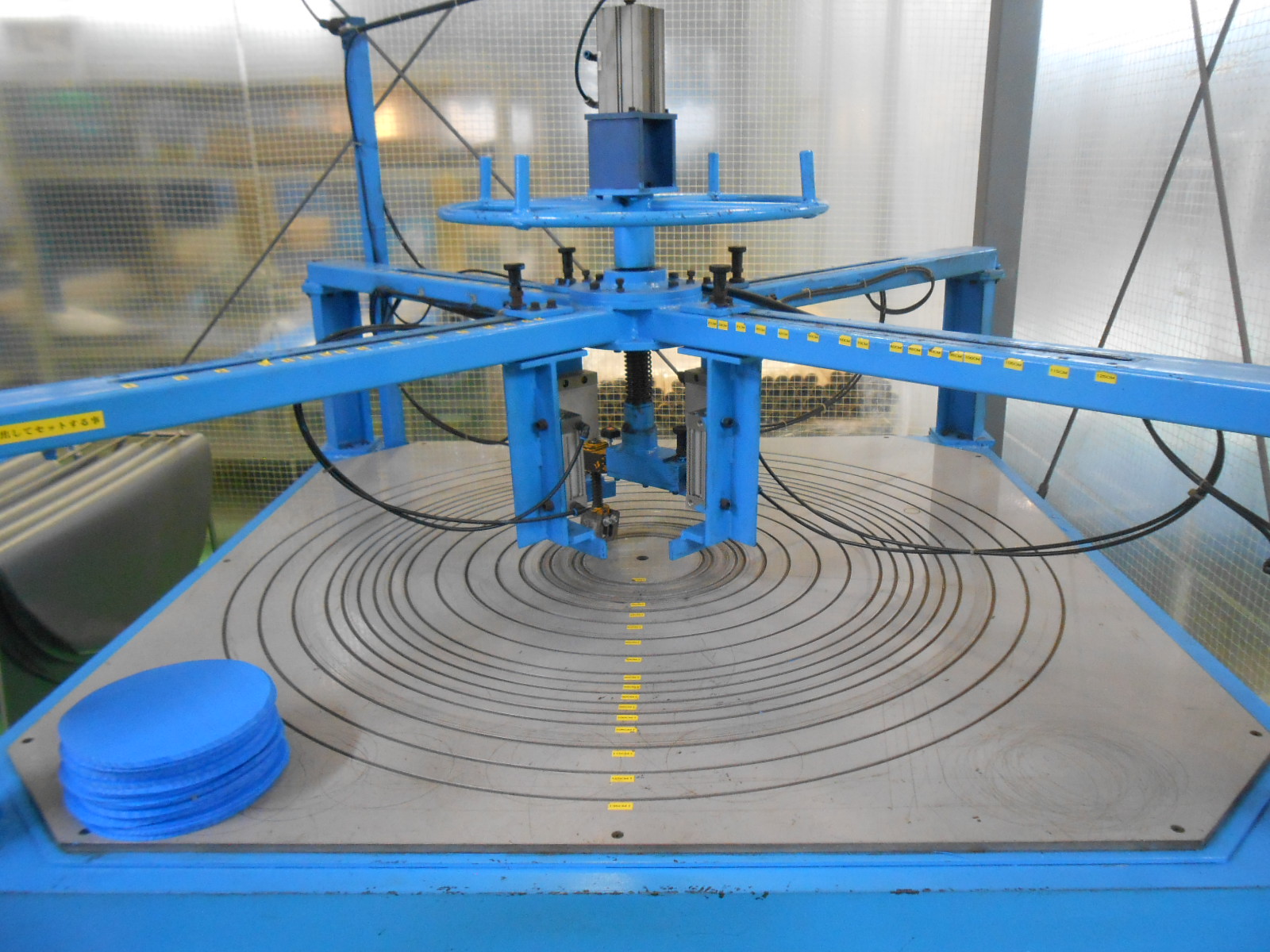

This is a cutting machine for making coverings for roll sides and this can cut into various sizes with just one machine!

This will allow to make a perfect sized covering for each roll.

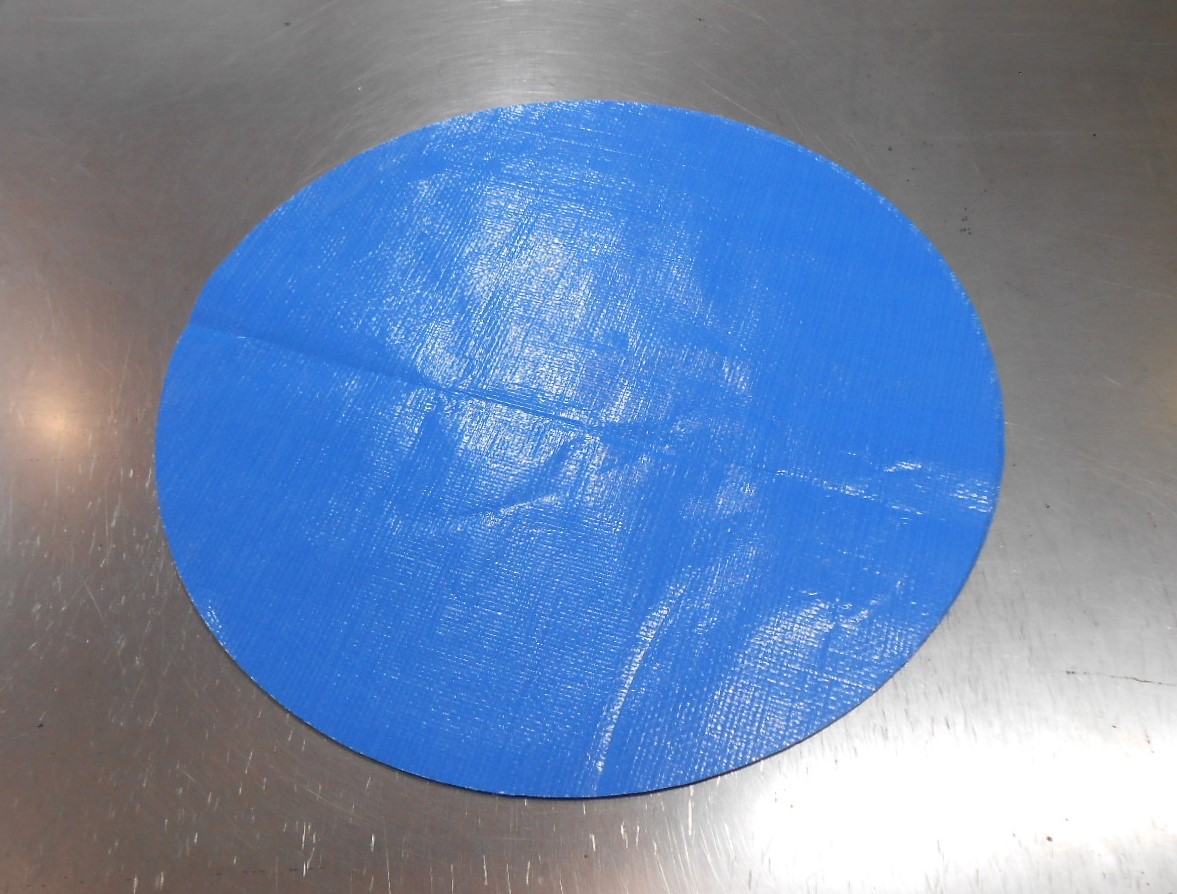

Below, it shows you the coverings we use to cover the sides of the roll and these are all made with PE tarp.

Of course, these coverings are made from our product.

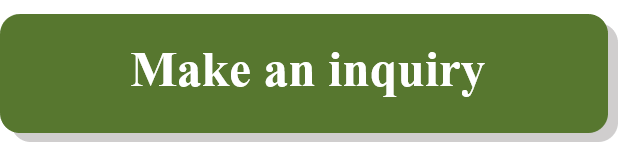

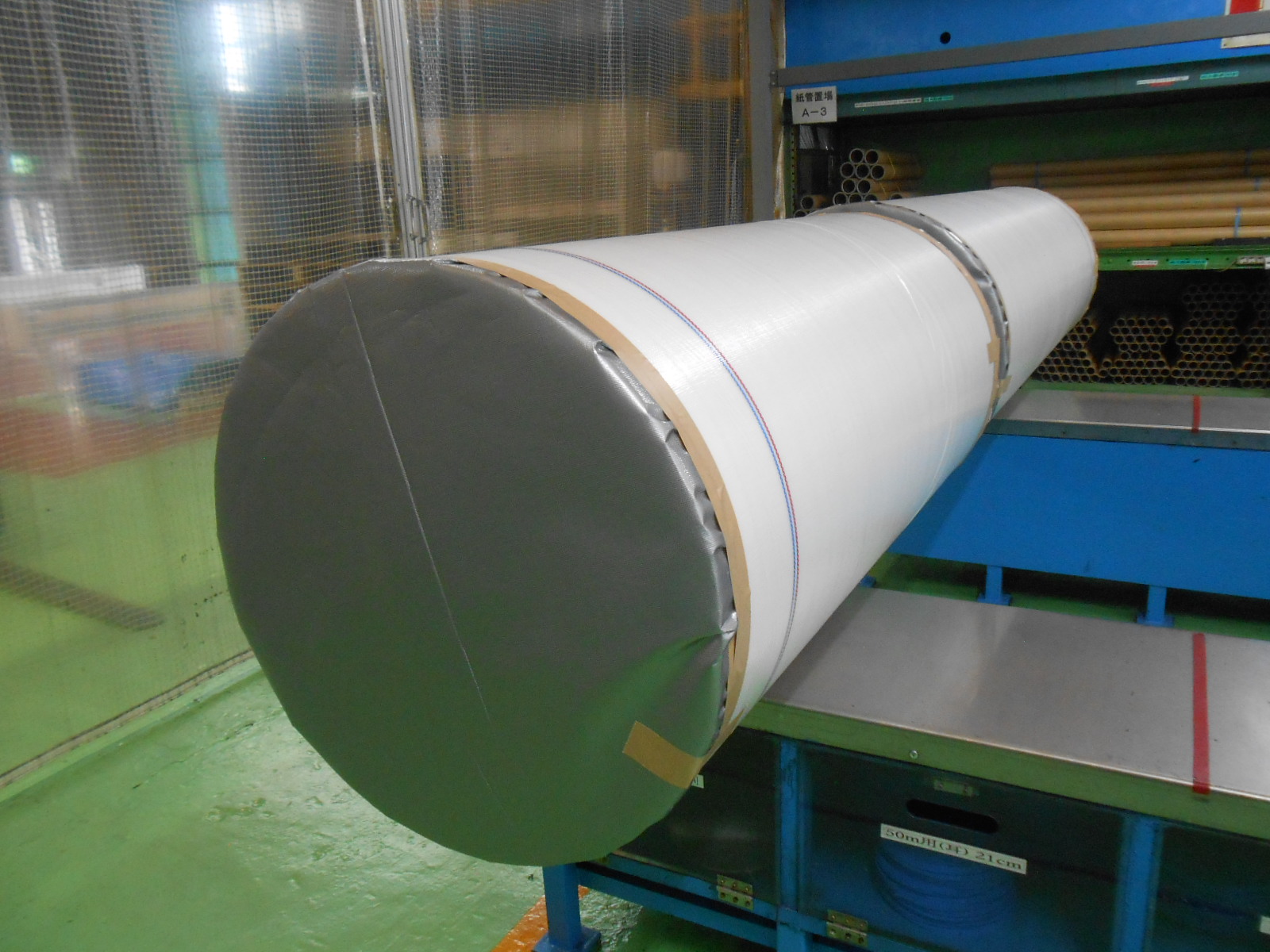

This is how our product will look like when shipping and all of our rolled products will be covered like this.

We are able to adjust width and length to your preference and

we make sure that our products won’t get damaged during the shipment.

If there are any concerns, please feel free to contact us.