Heavy Duty Shelter Fabrics

Build-To-OrderProducts with this logo are Build-To Order. Click here to learn more.

Build-To-OrderProducts with this logo are Build-To Order. Click here to learn more.

Custom-made availableProducts with this logo can be made according to your requests. Click here to learn more.

Custom-made availableProducts with this logo can be made according to your requests. Click here to learn more.

Made in JapanProducts with this logo are made in Hagihara Industries' Japan factory.

Made in JapanProducts with this logo are made in Hagihara Industries' Japan factory.

Various ColorsProducts with this logo have a variety of colors.

Various ColorsProducts with this logo have a variety of colors.

UV StabilizedProducts with this logo contains UV stabilizer.

UV StabilizedProducts with this logo contains UV stabilizer.

Environmentally FriendlyProducts with this logo uses safe material and components which are harmless to the environment and health.

Environmentally FriendlyProducts with this logo uses safe material and components which are harmless to the environment and health.

Heavy duty PE laminated cloth with high UV resistance performance.

- Feature

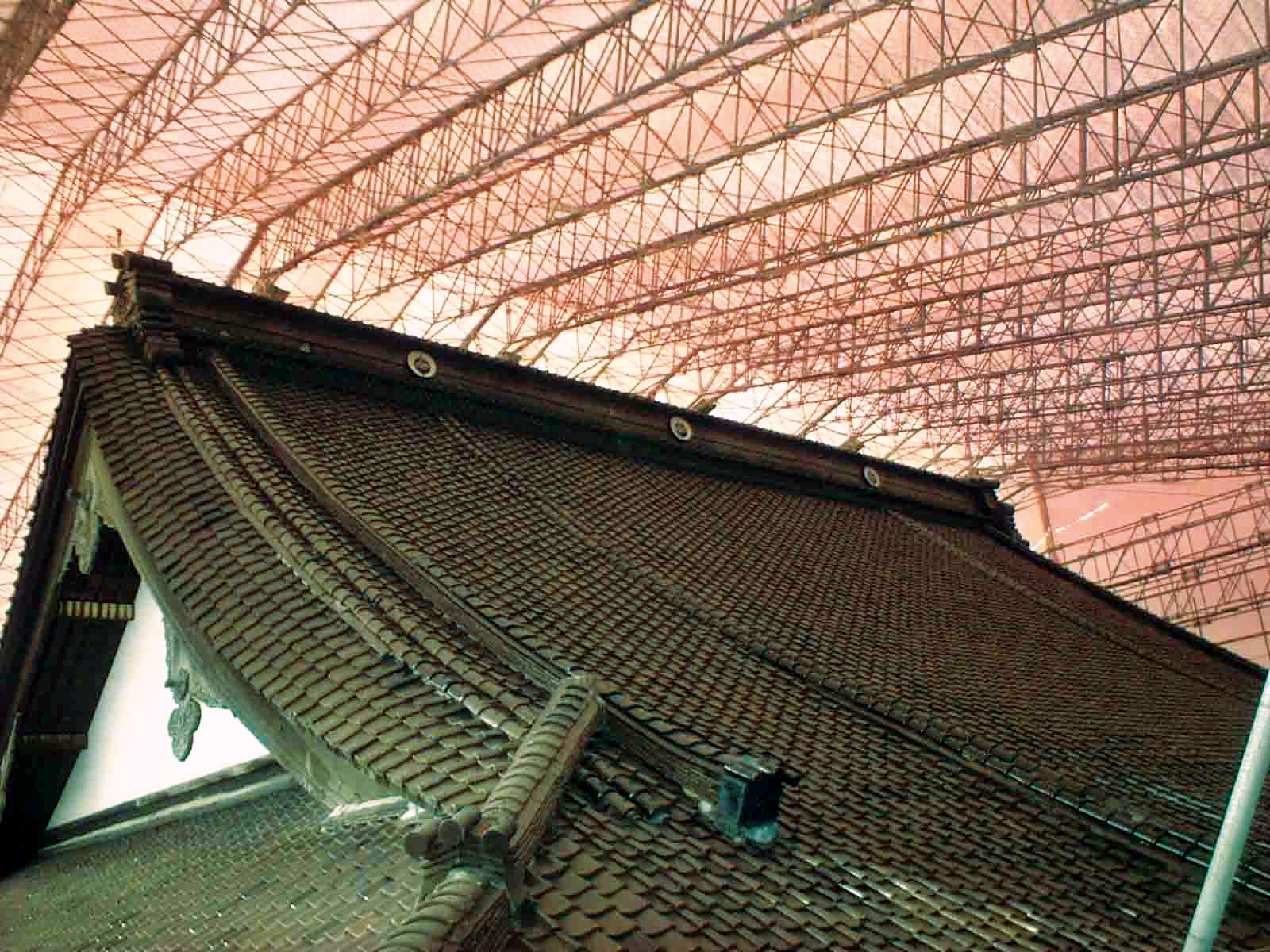

- Designed for huge shelter membrane. High UV performance, good strength and durability.

- Use

- Structure membrane.

- Material

- Polyethylene

- Color

- Any color

- Origin

- Made in Japan

Product Information

For more information, please contact us from here!

*Basically for companies who can import from Japan

1. Tarpee Titan UV (24mil, 12oz/yd2) (410gsm, 0.62mm)

2. Tarpee Titan FR (26mil, 12.2oz/yd2) (415gsm, 0.65mm)

3. Strong Master #23 UV (23mil, 13.1oz/yd2) (444gsm, 0.58mm)

4. Strong Master #23 FR (23mil, 11.9oz/yd2) (403gsm, 0.58mm)

5. Tarpee Xtra (21mil, 9.6oz/yd2) (327gsm, 0.54mm)

6. Strong Master #20 (20mil, 9.2oz/yd2) (312gsm, 0.54mm)

7. Origin Max (19mil, 8.2oz/yd2) (278gsm, 0.475mm)

8. Tarpee Origin 1414 (17mil, 7.5oz/yd2) (253gsm, 0.425mm)

Properties

| Weight | 410g/m² | 12oz/yd² |

|---|---|---|

| Thickness | 0.62mm | 24mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 2600N/5cm (JIS 1096) | 400lbs (ASTM D751) |

|---|---|---|---|

| Weft | 2500N/5cm (JIS 1096) | 400lbs (ASTM D751) | |

| Elongation | Warp | 14% (JIS 1096) | 15% (ASTM D751) |

| Weft | 14% (JIS 1096) | 16% (ASTM D751) | |

| Tear Strength | Warp | 450N (JIS 1096) | 155lbs (ASTM D4533) |

| Weft | 450N (JIS 1096) | 130lbs (ASTM D4533) | |

| Puncture Strength | 105lbs (ASTM D4833) | ||

※The above figures are measured values, not guaranteed values.

Properties

| Weight | 415g/m² | 12.2oz/yd² |

|---|---|---|

| Thickness | 0.65mm | 26mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 2600N/5cm (JIS 1096) | 360lbs (ASTM D751) |

|---|---|---|---|

| Weft | 2400N/5cm (JIS 1096) | 390lbs (ASTM D751) | |

| Elongation | Warp | 14% (JIS 1096) | 16% (ASTM D751) |

| Weft | 14% (JIS 1096) | 19% (ASTM D751) | |

| Tear Strength | Warp | 410N (JIS 1096) | 135lbs (ASTM D4533) |

| Weft | 430N (JIS 1096) | 135lbs (ASTM D4533) | |

| Puncture Strength | 105lbs (ASTM D4833) | ||

※The above figures are measured values, not guaranteed values.

Properties

| Weight | 444g/m² | 13.1oz/yd² |

|---|---|---|

| Thickness | 0.58mm | 23mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 380lbs (ASTM D751) |

|---|---|---|

| Weft | 350lbs (ASTM D751) | |

| Elongation | Warp | 16% (ASTM D751) |

| Weft | 16% (ASTM D751) | |

| Tear Strength | Warp | 130lbs (ASTM D2261) |

| Weft | 130lbs (ASTM D2261) | |

| Puncture Strength | 145lbs (ASTM D4833) | |

※The above figures are measured values, not guaranteed values.

Properties

| Weight | 403g/m² | 11.9oz/yd² |

|---|---|---|

| Thickness | 0.58mm | 23mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 2400N/5cm (JIS 1096) | 380lbs (ASTM D751) |

|---|---|---|---|

| Weft | 2300N/5cm (JIS 1096) | 350lbs (ASTM D751) | |

| Elongation | Warp | 14% (JIS 1096) | 16% (ASTM D751) |

| Weft | 15% (JIS 1096) | 16% (ASTM D751) | |

| Tear Strength | Warp | 450N (JIS 1096) | 130lbs (ASTM D2261) |

| Weft | 400N (JIS 1096) | 130lbs (ASTM D2261) | |

| Puncture Strength | 145lbs (ASTM D4833) | ||

| Flame Retardant Test | Passed (NFPA-701) | ||

※The above figures are measured values, not guaranteed values.

Properties

| Weight | 327g/m² | 9.6oz/yd² |

|---|---|---|

| Thickness | 0.54mm | 21mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 2100N/5cm (JIS 1096) | 320lbs (ASTM D751) |

|---|---|---|---|

| Weft | 2000N/5cm (JIS 1096) | 310lbs (ASTM D751) | |

| Elongation | Warp | 17% (JIS 1096) | 17% (ASTM D751) |

| Weft | 17% (JIS 1096) | 16% (ASTM D751) | |

| Tear Strength | Warp | 380N (JIS 1096) | 135lbs (ASTM D4533) |

| Weft | 370N (JIS 1096) | 125lbs (ASTM D4533) | |

| Puncture Strength | 105lbs (ASTM D4833) | ||

※The above figures are measured values, not guaranteed values.

Properties

| Weight | 312g/m² | 9.2oz/yd² |

|---|---|---|

| Thickness | 0.54mm | 20mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 2050N/5cm (JIS 1096) | 342lbs (ASTM D751) |

|---|---|---|---|

| Weft | 2050N/5cm (JIS 1096) | 303lbs (ASTM D751) | |

| Elongation | Warp | 17% (JIS 1096) | 23% (ASTM D751) |

| Weft | 16% (JIS 1096) | 23% (ASTM D751) | |

| Tear Strength | Warp | 400N (JIS 1096) | 123lbs (ASTM D2261) |

| Weft | 400N (JIS 1096) | 120lbs (ASTM D2261) | |

| Puncture Strength | 139lbs (ASTM D4833) | ||

※The above figures are measured values, not guaranteed values.

| Weight | 278g/m² | 8.2oz/yd² |

|---|---|---|

| Thickness | 0.475mm | 19mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 1780N/5cm (JIS 1096) | 280lbs (ASTM D751) |

|---|---|---|---|

| Weft | 1610N/5cm (JIS 1096) | 280lbs (ASTM D751) | |

| Elongation | Warp | 17% (JIS 1096) | 19% (ASTM D751) |

| Weft | 19% (JIS 1096) | 19% (ASTM D751) | |

| Tear Strength | Warp | 280N (JIS 1096) | 75lbs (ASTM D4533) |

| Weft | 280N (JIS 1096) | 75lbs (ASTM D4533) | |

| Puncture Strength | 145lbs (ASTM D4833) | ||

※The above figures are measured values, not guaranteed values.

Origin Max has been used as structure membrane in Singapore for decades. In 2020, Origin Max was used for making medical tents with the pandemic of COVID-19. The reason why it has been chosen for a long time are that it has UV resistance, straight warp and weft, good strength, and beautiful colors.

(Tents for local festival, in Aug. 2019)

Tarpee Origin 1414  Properties

Properties

| Weight | 253g/m² | 7.5oz/yd² |

|---|---|---|

| Thickness | 0.425mm | 17mil |

| Temperature Range | -30℃ to + 70℃ | |

Performance

| Tensile Strength | Warp | 1700N/5cm (JIS 1096) | 280lbs (ASTM D751) |

|---|---|---|---|

| Weft | 1600N/5cm (JIS 1096) | 270lbs (ASTM D751) | |

| Elongation | Warp | 17% (JIS 1096) | 17% (ASTM D751) |

| Weft | 16% (JIS 1096) | 18% (ASTM D751) | |

| Tear Strength | Warp | 250N (JIS 1096) | 60lbs (ASTM D4533) |

| Weft | 270N (JIS 1096) | 65lbs (ASTM D4533) | |

| Water Pressure | 180kPa | ||

※The above figures are measured values, not guaranteed values.