Choosing the right loom is a shortcut to perfect Woven Fabrics

We hear quite a lot of concerns about weft like,

“We need straight weft for physical property .” or ” We’re bit conscious about weft not going straight.”

Well, we may be able to solve your concerns because we have 3 different types of looms in our company!

All of the looms have their own good points and bad points so we use different loom

depending on what products we are making.

Let us introduce our looms and hope we could be your solution in some way.

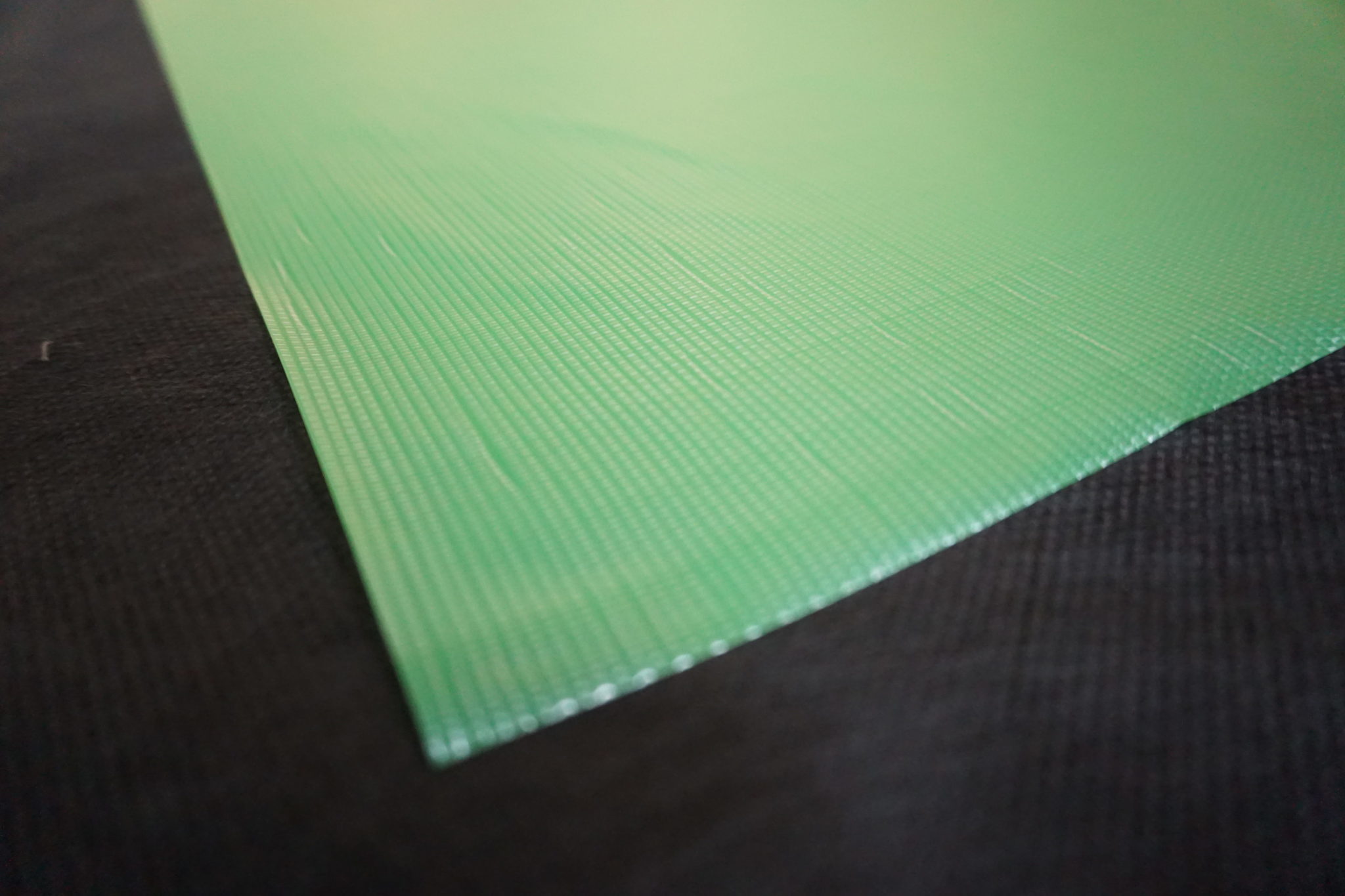

Flat Loom (Sulzer & Rapier)

Sulzer loom that we have at our company can weave approximately 4m wide

and what is good about Sulzer loom is that the weft goes straight.

Weaving pattern is beautiful and there are not so much difference in tear strength because it has straight weft.

We know that straight weft plays important role in tear strength.

It can also weave thick yarn, so it can produce wide range of fabrics

and almost all of our laminated woven cloth is woven by Sulzer loom.

| ▼Origin Max | ▼Horticover | |

|

|

Water Jet

As you can guess from its name, Water Jet uses water to project yarn.

Unlike Sulzer loom, it can not produce wide-width fabric but its productivity is faster than Sulzer loom.

It is not suitable for fabrics that can not get wet so we mainly produce

sandbags and fabrics for adhesive tape.

| ▼Super UV sandbag | ▼Fabric for adhesive tape | |

|

|

Circular

Circular is suitable for making fabrics for FIBCS.

Warps are lined up vertically and weft goes around the machine in circle.

This allows to make a fabric in tube shape which is suitable for making flexible container bag.

However, there is a limitation in the width due to the size of the machine, so please contact us for more detail.

| ▼Flexible Container Bag (FIBCS) |

|

If you have any concerns or having troubles with your woven fabrics, please feel free to contact us.

We are more than happy to be your help.